uPVC windows making machine

Sun Doors & Windows - Quality Beyond Trust

SUN uPVC Doors and Windows Product Range

When passion meets excellence, unbelievable things come into existence. Driven by such relentless spirit, a group of highly qualified and proficient bunch of people has established manufacturing facility focusing on innovative uPVC Doors and Windows.

uPVC Welding Machine

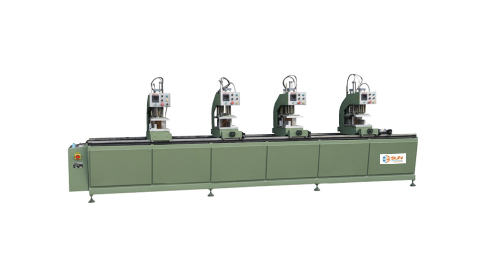

Four-head welding machine for PVC window HJ02-4500*4/4*A

Features

Suitable for welding PVC profile. It also can weld normal white profile by change the special clamper

Adopt programmable controller (PLC) ensures the machine running more steady and reliable.

Double pressing function ensures higher welding strength.

The pressure of front and back clamer is adjustable separately, so as to improve the planeness of the welding corner

The heads can be used individually, combinatively or jointly as well as be combined as will.

No. 2﹟、3﹟、4﹟ head can horizontal moving so that realized all kinds of welding combination.

The fourth head can be used for welding variable angle with the special mold and the angle range from 30°~180°.

Professional mold configuration, can provide the design for different profiles ensure the welding quality. (optional)

Welding seam is about 0.10-0.15mm. The welding effect much better for the laminate layer thickness>0.25mm color pvc profile (seamless model)

Technical Specifications

| Model | Four-head | Three-head | Two-head |

| Input power source | 380V/50Hz | 220V/50Hz | |

| Total power | 4.5Kw | 3.5Kw | 2.5Kw |

| Working air pressure | 0.5~0.8MPa | ||

| Air consumption | 200L/min | 150 L/min | 100 L/min |

| Height of welded profile | 20-120mm 20-170mm(optional) | ||

| Width of welded profile | 0-120mm | ||

| Welded range | 400-4500mm | 400-3500mm | |

| Dimension | 5400×1100×1650mm | 4400*1100*1650mm | |

| Weight | 1500kg | 1300Kg | 1100Kg |

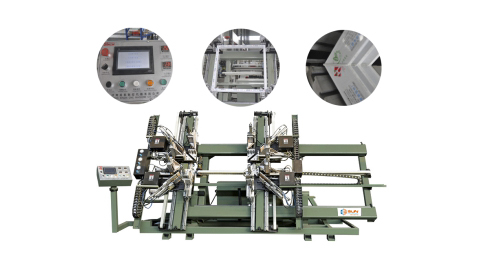

4-Corner welding machine for UPVC Window Profiles SHP4-CNC-180*1800*3000A

Features

Suitable welding pvc window, especially for big output high quality manufactuer.

Top grade PVC window welding machine.

One working cycle, one frame or sash fully automatically.

Using industrial-grade servo control system, the size of the change fast, high-precision repeat length.

Ball screw shaft ensure moving precision.

Square bearing system guarantee clamping, heating plate, locating plate moving precision & reliable performance.

By monitoring the torque servo system to achieve automatic pretensioners corners to ensure the accuracy of welding

Operate computer touch screen for full color, clear user interface, intuitive, easy to use.

Solid machinery base and structure ensure long life service with high dimension accuracy.

Imported linear bearing system kept the running stable

Vertical type is an ergonomically favorably position for the operator inserting upper profile.

Pressure protection: achieving effective quality control.

Automatic fault monitoring tips

Technical Specifications

| Input Voltage | 3N~50Hz 380V/220V or Customer specification |

| Input Power | 9(kw) |

| Operation Air Pressure | 0.5~0.8(MPa) |

| Air Consumption | 200(L/min) |

| Welding profile | 25~160(mm) |

| Welding Width | 0-120 (mm) |

| Welding Range | 400×400~1800×3000 (mm) |

| Overall Dimension | 5000×2000×2850(mm) |

| Machine Weight | 3000(kg) |

Single-head variable-angle welding machine for uPVC window SHD01-120

Features

Specially for 30-180 degree angle welding.

PLC controlled machinery working.

Two separate clamping device control for easy operation.

Technical Specifications

| Air Pressure | 0.5~0.8MPa |

| Air Consumption | 50L/min |

| Input Voltage | 220V 50Hz or Customer specification |

| Input Power | 1.2kw |

| Welding Height | 20~120mm |

| Welding Width(Max) | 330mm |

| Overall Dimension | 960×900×1460mm |

| weight | 240kg |

UPVC single-head welding machine HJ02-120

Features

Most economical PVC window welding machinery for limit budge investor.

PLC controlled machinery working.

90 degree welding, V welding ,30—180 degree is possible on this machine.

Technical Specifications

| Air Pressure | 0.5~0.8MPa |

| Air Consumption | 50L/min |

| Input Voltage | 220V 50Hz or Customer specification |

| Input Power | 1.2kw |

| Welding Height | 20~120mm |

| Welding Width(Max) | 120 mm |

| Overall Dimension | 900×750×1850mm |

| weight | 260(kg) |

Four-head seamless welding machine for UPVC window HJ-V4

Features

Advanced European style for high end market.

0.2mm and 2 mm welding auto change by switch.

Variable angle welding between 30 to 180 degree on last head.

Rigid grasp structure adopted to the profile positioning system, which strictly guarantee welding loss and high welding accuracy.

V-shape heating plate ensure high welding corner strength and small tolerance.

Imported square bearing system guarantee clamping, heating plate, locating plate moving precision & reliable performance.

Solid machinery base and structure ensure long life service with high dimension accuracy.

Profile fixture ordered separately can meet various profiles' processing requirement

Pneumatic brake device.(optional)

Low pressure Alarm Device

Technical Specifications

| Model | Four-head | Three-head | Two-head |

| Input power source | 380V/50Hz | 220V/50Hz | |

| Total power | 4.5Kw | 3.5Kw | 2.5Kw |

| Working air pressure | 0.5~0.8MPa | ||

| Air consumption | 270L/min | 210L/min | 180 L/min |

| Height of welded profile | 20-120mm 20-260mm(optional) | ||

| Width of welded profile | 0-120mm | ||

| Welded range | 400-4500mm | 400-3500mm | |

| Dimension | 5400×1100×1650mm | 4400*1100*1650mm | |

| Weight | 1900kg | 1500Kg | 1300Kg |

Welding Cleaning Production Line for UPVC Doors and windows SHQXJ01

Features

This welding-cleaning production line uses horizontal structure for stable running.

It realizes automatic size error compensation, high processing precision and high stability.

Unique positioning, heating integrated structure, movement and the use of side rails deputy, simple, stable and reliable.

welding head dual belt drive mechanism, high positioning accuracy

welding head adopt high-simultaneous welding technology, welding and soldering aesthetic appearance of the finished angular intensity The welding size can automatically compensate, welding products, accurate size.

Special profiles can be quickly replaced magnetic plate, improve work efficiency.

According to user needs, can achieve double sash window frame or welding.

Angle seam cleaning units with high efficient servo drive system, plastic doors and windows automatically to quickly clean up almost all of the weld.

It is not necessary to change cutters to process more than one hundred profiles

Error compensation between arc and straight line is possible and gives good cleaning appearance.

Technical Specifications

| Model | Four-head | Three-head | Two-head |

| Input power source | 380V/50Hz | 220V/50Hz | |

| Total power | 4.5Kw | 3.5Kw | 2.5Kw |

| Working air pressure | 0.5~0.8MPa | ||

| Air consumption | 270L/min | 210L/min | 180 L/min |

| Height of welded profile | 20-120mm 20-260mm(optional) | ||

| Width of welded profile | 0-120mm | ||

| Welded range | 400-4500mm | 400-3500mm | |

| Dimension | 5400×1100×1650mm | 4400*1100*1650mm | |

| Weight | 1900kg | 1500Kg | 1300Kg |

Cutting Machine

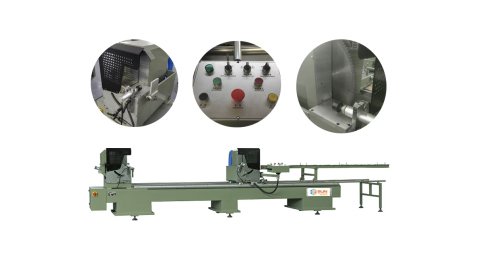

Double-head precison cutting machine for PVC window SSJ07-450*3600

Features

90°, inside 45, plastic profile. Various angle cutting is available.

Right head moving manually on the linear bearing rail.

Micro cutting length adjustment device ensure precision and easy operation.

With the additional intermediate supporting mechanism of equivalent length, convenient feed and location.

The linear guiding pair ensures steady processing accuracy.

Saw blade straight feeding from inside to outside stably and precisely by pneumatic cylinder.

Carbide Saw blade ensure high cutting surface precision.

Two hand safety operation

Technical Specifications

| Air Pressure: | 0.5-0.8MPa |

| Air Consumption | 50(L/min) |

| Input Voltage | 3N-50Hz 380/220V or As Customer Specification |

| Input Power | 4.5(Kw) |

| Saw Blade Diameter | Φ 450 |

| Motor Rotary Speed | 2800(r/min) |

| Cutting Height | 1200(mm) |

| Cutting Width | 120(mm) |

| Cutting Length | 45° max 3700mm Min 550mm 90° max 3700mm Min 400mm |

| Overall Dimension: | 4500mm*1170mm*1400mm |

| Weight: | 1500(kg) |

Double-head cutting machine for PVC profile SJ02-3500

Features

For 45°~90°cutting plastic and aluminum profile. Various angle cutting is available.

Cutting limitation adjustable

Adopting the turntable location technology, high cutting precision.

Vertical and horizontal pneumatic clamping to ensure stable profile fixing

With two saw head, the left saw head is fixed, the right saw head can move in left and right according to the cut length.

With the additional intermediate supporting mechanism of equivalent length, convenient feed and location.

The saw head do fixed axis cycloid feed on the worktable’s vertical side, cutting operation stable and reliable

Technical Specifications

| Air Pressure: | 0.4-0.6MPa |

| Air Consumption | 200(L/min) |

| Input Voltage: | 3N-50Hz 380/220V or As Customer Specification |

| Input Power: | 3(Kw) |

| Saw Blade Diameter: | Φ 450 |

| Motor Rotary Speed: | 2800(r/min) |

| Cutting Height: | 200(mm) |

| Cutting Width | 120(mm) |

| Cutting Length: | 45° max 3700mm Min 550mm 90° max 3700mm Min 400mm |

| Overall Dimension: | 4500mm×1170mm×1400mm |

| Weight: | 1500(kg) |

PVC window single-head cutting machine SJ01

Features

For 45°~90°cutting plastic and aluminum profile

Suitable for profiles with thicknesses: 0~100mm, and lengths: 0~3500mm

Adopt the turntable location technology, high cutting precision.

Adopt the pneumatic clamping mechanism, calming operation reliable and quick.

The shaft is made of high-quality carbon structural steel, good endurance.

The saw head do fixed axis cycloid feed on the worktable’s vertical side, cutting operation stable and reliable.

Technical Specifications

| Power supply | 380V/50Hz or As Customer Specification |

| Air pressure | 0.4Mpa~0.7Mpa |

| Air consumption | 80L/min |

| Motor power | 1.5Kw |

| Cutting height | 100mm |

| Locating length | 0~3500(mm) |

| Rotational speed of motor | 3300r/min |

| Saw blade diameter | 350mm |

| Weight | 200Kg |

| Overall dimensions | 1000×1120×1450(mm) |

PVC window V-cutting machine LJVW-60

Features

Automatic V-cutting of UPVC Window profile

Two hand safety operation

Pneumatic clamping

Adjustable V-notch depth based on different profile.

Adjustable feeding speed.

Technical Specifications

| Air Pressure | 0.5~0.8(MPa) |

| Air Consumption | 50(L/min) |

| Input Voltage | 380V 50HZ or as customer specification |

| Input Power | 1.5(Kw) |

| Spindle Rotary Speed | 2800(r/min) |

| Saw Blade Specification | ø300x3.2x ø30 |

| Cutting Height | 20~60(mm) |

| Cutting Width | 120(mm) |

| Cutting Length | 300~1600(mm) |

| Overall Dimension | 1800×1380×1300(mm) |

| Weight | 220(kg) |

Double-head cutting machine for PVC profile SSJ06-3700

Features

90°, inside 45, outside 45 cutting plastic and aluminum profile. Various angle cutting is available.

Right head moving is driven by motor automatically and easily. Auto brake device.

Micro cutting length adjustment device ensure precision and easy operation.

With the additional intermediate supporting mechanism of equivalent length, convenient feed and location.

The linear guiding pair ensures steady processing accuracy.

Saw blade rotates smoothly due to high accuracy main spindle.

Saw blade straight feeding from inside to outside stably and precisely by pneumatic cylinder. Optional Hydro-pneumatic feeding cylinder is available.

Carbide Saw blade ensure high cutting surface precision.

Two hand safety operation

Technical Specifications

| Air Pressure: | 0.4-0.6MPa |

| Air Consumption | 200(L/min) |

| Input Voltage: | 3N-50Hz 380/220V or As Customer Specification |

| Input Power: | 3(Kw) |

| Saw Blade Diameter: | Φ 450 |

| Motor Rotary Speed: | 2800(r/min) |

| Cutting Height: | 200(mm) |

| Cutting Width | 120(mm) |

| Cutting Length: | 45° max 3700mm Min 550mm 90° max 3700mm Min 400mm |

| Overall Dimension: | 4500mm×1170mm×1400mm |

| Weight: | 1500(kg) |

Double independent heads CNC Cutter/Router Machine M1530H

Features

Two spindles can be working synchronously as well as separately.

Whole machine is welded with seamless steel structure, the stability is excellent, not easy to be deformed.

The machine adopts gantry movement, it can process any kinds of materials freely.

Adopts Germany-made ball-screw on Z axis, having the character of high precision and long life-time. XY axes adopt rack and pinion transmission, having character of fast working, high efficiency and low cost.

Well compatibility: CAD/CAM designing software e.g. Type 3/ Artcam/ Castmate/ Wentai etc.

Has the function of re-carving after break point and power failure.

Adopting advanced DSP system with USB connection, operated with the handle, convenient operation. Our engraver can completely work off-line and do not take any computer resources.

Technical Specifications

| Model | CC-M1325BH2 | CC-A1530BH2 |

| working area | 1300*2500*250mm | 1500*3000*250mm |

| Working mode | Servo | |

| Operating system | Weihong Handle control system | |

| Spindle Motor | Air-cooling 3.5KW Spindle | |

| Diameter of cutter | φ3.175-φ20 | |

| Weight | 1100KG-1300KG | |

| Vacuum Pump | 5.5kw Water-coolling vacuum pump | |

| Software | CAD/DAM, Type 3/Artcam/Powermill/UG | |

| Standard Power | AC380V-/220V-Three Phase (Optional) | |

Copy Milling Machine

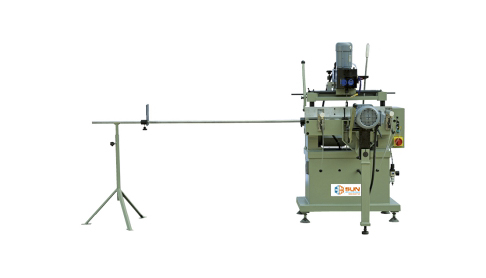

Lock groove processing machine for PVC window LSKC03-120

Features

Used for processing handles in three holes and the slots which for installing the hardware at the PVC and Aluminium profile.

The lock hole drill system opposite the operator, easy operation.

Routing to stops or universal template in 1:1 ratio

Handle wheel for easy adjusting milling height. Friendly using design

Adopt the high-speed copy-routing milling head

The three hole driller motor moves to behind of machine, so that make much more space for the worker

Horizontal triple drill and vertical copy router with special cutout working table to realize

one time finishing.

Technical Specifications

| Operation Air Pressure | 0.5~0.8(MPa) |

| Air Consumption | 30L/min |

| Input Voltage | 380V/50Hz or Customer specification |

| Main-Shaft Revolution | 12000(r/min) |

| Input Power | 2.25(kW)) |

| Cutter Diameter | φ5φ8(mm) |

| Copy Milling Range | 90×290(mm) |

| Overall Dimension | 1000×1130×1500(mm) |

| Machine Weight | 300(kg) |

Automatic 3-axis milling water-slot machine SCX03-3*60

Features

Used for processing handles in three holes and the slots which for installing the hardware at the PVC and Aluminium profile.

The lock hole drill system opposite the operator, easy operation.

Routing to stops or universal template in 1:1 ratio

Handle wheel for easy adjusting milling height. Friendly using design

Horizontal triple drill and vertical copy router with special cutout working table to realize

one time finishing.

Technical Specifications

| Air Pressure: | 0.5-0.8MPa |

| Air Consumption | 30(L/min) |

| Input Voltage: | 220V 50Hz Customer specification |

| Input Power: | 1.14kW |

| Diameter of milling cutter | Φ4*50/75mm Φ5*50/75mm or Customer Specification |

| Spindle Rotary Speed: | 26000(r/min) |

| Slot Depth | 30(mm)(Max) |

| Slot Length: | 30~60(mm) |

| Overall Dimension:&nbsnbsp; | 1950×860×1600(mm) |

| Weight: | 280(kg) |

Sealing cover milling machine SFX02-160

Features

Used for processing flute of sliding window sash of pvc profile

Adopt adjustable profile guiding plate, guiding size and location size can adjustable according to the profile, but need not change the guding plate

Can processing rectangle groove which in different width by using different cutters.

Technical Specifications

| Input Voltage: | 220V 50Hz Customer specification |

| Input Power: | 0.75kW |

| Diameter of milling cutter | Φ130mm |

| Spindle Rotary Speed: | 2800(r/min) |

| Max. dimension of cutting flute | 18*25mm |

| Overall Dimension: | 530×530×1100(mm) |

| Weight: | 80(kg) |

Lock groove processing machine for PVC window SSK02-100

Features

Used for processing handles in three holes and the slots which for installing the hardware at the PVC and Aluminium profile.

The lock hole drill system opposite the operator, easy operation.

Routing to stops or universal template in 1:1 ratio

Handle wheel for easy adjusting milling height. Friendly using design

Horizontal triple drill and vertical copy router with special cutout working table to realize

one time finishing.

Technical Specifications

| Operation Air Pressure | 0.5~0.8(MPa) |

| Air Consumption | 30L/min |

| Input Voltage | 380V/50Hz or Customer specification |

| Main-Shaft Revolution | 12000(r/min) |

| Input Power | 2.25(kW)) |

| Cutter Diameter | φ5φ8(mm) |

| Copy Milling Range | 90×290(mm) |

| Overall Dimension | 1000×1130×1500(mm) |

| Machine Weight | 300(kg |

Corner Cleaning Machine

PVC window V-corner cleaning machine SQJ05-120

Features

Professional used in cleaning the welding seam in 90°and “V” shape of PVC win-door.

The worktable sliding rail ensures the mullion in accurate location.

The special pneumatic compaction device make the profile under the good force so that ensure the quality of cleaning.

Upper and lower planning cutter is driven by pneumatic.

Hands to be operated at the same time, ensures the operator safety.

Technical Specifications

| Working air pressure | 0.5~0.8MPa |

| Air consumption | 100L/min |

| Processing profile height | 40~120mm |

| Processing profile width | 40~120mm |

| Dimension | 930×690×1300mm |

| Weight | 115kg |

PVC window corner cleaning machine SQJ01-120

Features

Professional used in cleaning the welding tumor in 90°corner of external for window frame and sash, the upper and lower of profile.

Adopt programmable controller (PLC) ensures the machine running more steady and reliable.

To clean the external angle in 90° in different ending of the welding seam by using different shapes of cutters.

The unique design for the special cutters to make them in stable working and have nice cleaning effect.

Safety guards for saw blade protection.

Technical Specifications

| Input power source | 380v/50Hz |

| Total power | 1.1kw |

| Working air pressure | 0.5-0.8MPa |

| Principal axis rotate speed | 2800r/min |

| Processing profile height | 25-120mm |

| Processing profile width | 25-120mm |

| Size | 1600*1285*1370mm |

| Weight | 270kg |

PVC window CNC corner cleaning machine JQK04-CNC-120

Features

Professional used in cleaning the welding tumor in 90°corner of external for window frame and sash, the upper and lower of profile.

It has multi-function such as vertical milling, saw milling and broaching and so on.

Two-axis CNC cleaning the corner of processing flow controlling make the operation is easy.

Adopts industry grade computer system, closed-loop controlling, ensures high precision.

Interface in figures and diagrams which can display directly the moving trace of the cutter.

It is simple, direct-viewing with the demonstrating program function, can set two-dimension processing programming by CNC controller

Equipped with USB connection, may connect with external store..

Technical Specifications

| Input power source | 380V/50Hz |

| Total power | 2.0Kw |

| Working air pressure | 0.5~0.8MPa |

| Air consumption | 200L/min |

| Diameter of milling cutter | 200mm |

| Principal axis rotate speed | 2800r/min |

| Processing profile height | 30~120mm |

| Processing profile width | 30~110mm |

| Dimension | 2000×1930×1500mm |

| Weight | 640kg |

PVC window CNC corner cleaning machine JQK04A-CNC-120

Features

Professional used in cleaning the welding tumor in 90°corner of external for window frame and sash, the upper and lower of profile as well as the groove of rubber strip.

It has multi-function such as vertical milling, saw milling and broaching and so on.

Two-axis CNC cleaning the corner of processing flow controlling make the operation is easy.

Adopts industry grade computer system, closed-loop controlling, ensures high precision.

Interface in figures and diagrams which can display directly the moving trace of the cutter.

It is simple, direct-viewing with the demonstrating program function, can set two-dimension processing programming by CNC controller.

Equipped with USB connection, may connect with external store.

The value can be stochastic keyed, revised the processing program on the spot, so that make the welding seam error can be cleaned up efficiently

Adopt the dust-cleaner which can clean the dust so that ensure the operator health.(OPTIONAL)

Conform to process high grade PVC window and door.

Technical Specifications

| Input power source | 380V/50Hz |

| Total power | 2.0Kw |

| Working air pressure | 0.5~0.8MPa |

| Air consumption | 200L/min |

| Diameter of milling cutter | 200mm |

| Principal axis rotate speed | 2800r/min |

| Processing profile height | 30~120mm |

| Processing profile width | 30~110mm |

| Dimension | 2000×1930×1500mm |

| Weight | 640kg |

Other Auxiliary Machines

steel punching machine for PVC window GYJ01-50

Features

Used for shearing the steel liner profile of PVC window and door.

This machine adopt hydraulic drive, running stably and reliable.

Much efficiency for punching V-corner hole.

Technical Specifications

| Input Voltage | 3N-50Hz 380/220V or As Customer Specification |

| Input Power | 1.5(Kw) |

| Max. shearing force | 60KN |

| Shearing travel | 5-30mm |

| Max. shearing thickness | 2mm |

| Oil capacity | 20L |

| Mould size | 250*200*215mm |

| Overall Dimension: | 700mm*950mm*1400mm |

| Weight: | 200(kg) |

PVC window arch bending machine SYH1800

Features

Special for bending UPVC window profile.

Electrical oil heating to warm up the profile to become soft.

Profile bending within the diameter 800~1800mm

Technical Specifications

| Input Voltage | 220V 50Hz or customer specification. |

| Input Power | 12kW |

| Heating Oil Groove Capacity | 0.2 |

| Bending Radian Diameter Range | 800~1800mm |

| Heating Temperature | 90~130 |

| Overall Dimension | 4500×2800×800mm |

| Weight | 600kg |

Screw drilling machine for PVC window LDJZ1-120

Features

Used for fastening the Reinforcement of the PVC window and door

Adopt PLC programming controller, it’s reliable and stable

The machine head is adjustable form front to back according to profile width. Front and back distance adjustment adopt infrared distance measurement, the location easy and accuracy.

Auto feeding and distributing screws by special feeding device, with screw inspection function, with high working efficiency, it’s the ideal machine for batch window and door factory

With standard two sets of 2M supporting bracket.

Can be customized four and six models.

Technical Specifications

| Air Pressure: | 0.5-0.8MPa |

| Air Consumption | 30(L/min) |

| Input Voltage | 3N-50Hz 380/220V or As Customer Specification |

| Input Power | 0.5(Kw) |

| Motor Rotary Speed | 2800(r/min) |

| Profile Height | 20-120(mm) |

| Max. thickness of metal | 2(mm) |

| Movable distand(F to B) | 20-70 mm |

| Overall Dimension: | 400mm*450mm*1600mm |

| Weight: | 200(kg) |

End milling machine for PVC window DX05-200

Features

PFor end milling of transom and door frames in UPVC and aluminum profile.

Automatic feeding.

Various angle mullion milling for arch window or other special shape window.

Hand wheel for different height adjustment.

Technical Specifications

| Operation Air Pressure | 0.5~0.8(MPa) |

| Air Consumption | 10L/min |

| Input Voltage | 380V/50Hz or Customer specification |

| Main-Shaft Revolution | 2800(r/min) |

| Input Power | 2.2kw |

| Max Processing Height | 100mm |

| Diameter of main shaft | 32mm |

| Locating plate rotating angle | -55 to +55 degree |

| Overall Dimension | 1150 *1150 * 1700 mm) |

| Machine Weight | 238kg |